Unirse TMAX, convertirse en un agente!

Unirse TMAX, convertirse en un agente!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Número de artículo.:

TMAX-YS-BZP200Pago:

L/C, T/T, Western Union, Credit Cards, PaypalOrigen del producto:

ChinaPuerto de embarque:

Xiamen PortPlazo de entrega:

5 Dayscertificado :

CE, IOS, ROHS, SGS, UL Certificategarantía :

Two years limited warranty with lifetime technical support

1.Introducción

1.1 Descripción general del equipo

TMAX-YS-BZP200 es una máquina apiladora automática de alta precisión con muchas características avanzadas para garantizar un apilamiento de electrodos estable, repetible y preciso. En su método de apilamiento en forma de "Z", los electrodos de ánodo y cátodo se apilan alternativamente con la película separadora en el medio.

1.2 Flujo de trabajo

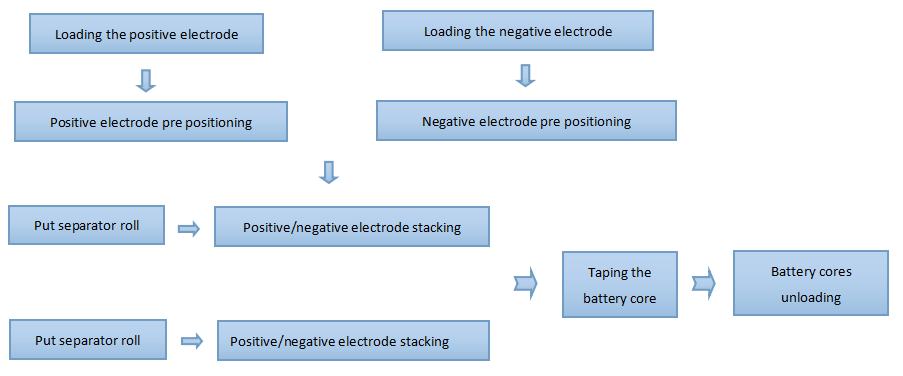

El separador toma la iniciativa de desenrollarse y es conducido a la mesa de apilamiento a través del mecanismo de tensión; la mesa de apilamiento hace que el separador se mueva hacia adelante y hacia atrás para colocar los electrodos; los electrodos positivo y negativo se sacan de las dos cajas de material de la izquierda mediante dos juegos de ventosas del manipulador respectivamente, y luego se apilan en la mesa de apilamiento después de un posicionamiento preciso; después del apilamiento, el manipulador transfiere el núcleo de la batería a la estación de encolado del rollo de cola, y el rollo de cola es automático; el separador se corta y se golpea automáticamente.

El diagrama de flujo del proceso es el siguiente:

1.3 Características del equipo

1.3.1 Separador: desenrollado activo; control de tensión; corrección de desviación del separador; eliminación electrostática del separador; precisión de alineación del separador ± 0,5 mm;

1.3.2 Alta precisión: mediante el posicionamiento preciso del electrodo, se garantiza que la precisión general del electrodo en el apilamiento será de ±0,3 mm;

1.3.3 Alta eficiencia: la velocidad de apilamiento puede alcanzar 0,6 s~1 s/pieza;

1.3.4 Protección contra el polvo: la caja de material y el preposicionamiento están equipados con un mecanismo eficaz de protección contra el polvo;

1.3.5 Confiabilidad: los módulos con alta precisión y movimiento constante del equipo se fijan con pasadores de localización;

1.3.6 Número de apilamiento de electrodos preciso: protección de detección de electrodos faltantes; mecanismo anti electrodo extra; Mecanismo de detección de electrodos adicionales, que evita eficazmente que se acumulen electrodos adicionales en el núcleo de la batería.

1.3.7 Detección de la pestaña del electrodo: detecta el electrodo con la pestaña dañada y evita que se apile en el núcleo de la batería por error.

1.3.8 Se puede confirmar de acuerdo con los requisitos del cliente, realizar el cambio de la caja de material mediante el manejo del manipulador y cooperar con la línea de producción automática para cargar y descargar automáticamente la caja de material.

1.3.9 Se puede confirmar según los requisitos del cliente y los núcleos de batería apilados se pueden descargar automáticamente a la siguiente línea de montaje.

2.Composición estándar

|

Nº |

Nombre de los componentes |

Cantidad/juego |

Observación |

|

1 |

Mecanismo de alimentación automática de la caja de material |

2 |

Caja de material especial tipo enchufable, dos juegos para electrodos positivos y negativos, tamaño ajustable; |

|

2 |

Mecanismo auxiliar de carga de electrodos |

2 |

Mecanismo de cepillo y agitador; dispositivo de soplado de aire y succión de polvo; evitar problemas de electrodos adicionales |

|

3 |

Mecanismo de elevación y carga de electrodos |

2 |

Garantizar que el manipulador absorba los electrodos de manera confiable; alarma de apagado automático en caso de escasez de material |

|

4 |

Mecanismo de control de tensión del separador |

1 |

Separador desenrollado activo, tensión constante |

|

4.1 |

Sistema de corrección del separador |

1 |

Desenrollar y corregir la desviación; |

|

5 |

Módulo de preposicionamiento mecánico |

2 |

Posicionamiento mecánico preciso; dispositivo de recolección de polvo; y equipado con mecanismo de recolección de polvo |

|

5.1 |

Detección de piezas múltiples |

2 |

Detección de espesor ultrasónica para evitar que entren piezas adicionales en el núcleo de la batería; |

|

6 |

Manipulador de apilamiento |

2 |

El servoaccionamiento garantiza que el manipulador pueda agarrar y colocar los electrodos de forma fiable |

|

7 |

Mecanismo de ventosa de carga |

4 |

Dos juegos de tipo boquilla de vacío y dos juegos de tipo placa de succión |

|

8 |

Mesa de apilamiento |

1 |

Traslación y elevación de la mesa de apilamiento por servoaccionamiento: husillo de bolas preciso para realizar el movimiento alternativo de la mesa de apilamiento |

|

9 |

Módulo de sujeción del manipulador |

1 |

El manipulador realiza la transferencia del núcleo de la batería automáticamente |

|

10 |

Mecanismo de corte del separador |

1 |

Un juego de mecanismo de cuchilla caliente, cortado después de determinar la longitud de la bobina de cola |

|

11 |

Mecanismo de pegado lateral de cinta adhesiva |

1 |

Se puede configurar la posición y la cantidad de adhesivo en los lados alrededor (incluido el centro de la pestaña) |

|

12 |

Mecanismo de descarga automática |

1 |

Apilamiento y descarga automáticos del núcleo de la batería, extracción por lotes, reducción de la demanda manual |

|

13 |

Sistema operativo eléctrico |

1 |

Funcionamiento con pantalla táctil, con parada de emergencia, interruptor de encendido y otros botones |

|

14 |

Sistema de control |

1 |

Los electrodomésticos y circuitos de gas se instalan en el interior del equipo, ahorrando espacio y siendo de fácil mantenimiento |

|

15 |

Sustrato de bastidor |

2 |

Color: gris computadora |

|

16 |

Cubierta antipolvo |

1 |

1 juego de cubierta de plexiglás de aleación de aluminio, con interruptor de enclavamiento e interruptor de emergencia |

|

17 |

Mecanismo de succión de polvo |

1 |

Recolección de polvo por soplador; preposicionamiento, caja de material |

|

Artículo |

Especificación (mm) |

|

Longitud del núcleo de la batería L |

135-190 |

|

Ancho del núcleo de la batería W |

80-150 |

|

Grosor de la batería T |

3.5-20 |

|

Longitud de la pestaña |

6-20 |

|

Bosquejo del núcleo de la batería |

|

|

|

|

Artículo

Especificación

Tiempo de apilamiento único

0,65 s~1,3 sï¼Relacionado con el tamaño del electrodoï¼

Tiempo auxiliar de celda única

â¤10S

Precisión del electrodo adyacente y del separador

Desviación central ±0,5 mm

Precisión de alineación de la cara del extremo del separador

±0,4 mmï¼excepto el separador de rollo de colaï¼

Precisión de alineación del electrodo adyacente

±0,3 mm

Precisión de alineación general del electrodo

±0,3 mm

Número de apilamiento

Se puede configurar dentro del rango de espesor

Descarga

Apilar los núcleos de la batería y descargarlos

Movilidad de cultivos

95%

Tasa de aprobación

98%

|

Artículo |

Especificación |

|

Dimensiones de la máquina |

1700mmï¼Lï¼Ã2350mmï¼<9 48Dï¼Ã1877mmï¼Hï¼ (el El tamaño estará sujeto al diseño final) |

|

Peso de la máquina/rodamiento |

Aproximadamente 1000KGï¼ 450kg/m2 |

|

Fuente de alimentación |

AC220V±10ï¼ï¼monofásicoï¼ Potenciaï¼3KVAï¼frecuenciaï¼50Hz |

|

Aire comprimido |

0.5~0.7MPa(5kgf~7kgf/cm2)ï¼Consumoï¼200L/minï¼seco aire |

|

Temperatura/humedad |

5~35°Cï¼5~55% |

|

Aire/polvo |

Sin gas salado, gas tóxico y corrosivo; sin polvo conductor |

|

Campo magnético y vibración |

No habrá ningún límite magnético que afecte al dispositivo; no habrá impacto ni vibración obvia |

|

Diagrama general del modelo |

|

1 paquete estándar exportado: protección anticolisión interna, embalaje externo en caja de madera para exportación.

2 Envío por expreso, aéreo o marítimo según los requisitos del cliente para encontrar la forma más adecuada.

3 responsable del daño durante el proceso de envío, cambiará la pieza dañada de forma gratuita.

Anterior :

Mezcladora planetaria del vacío 30L para el procesamiento de la mezcla de células de bolsaPróximo :

Máquina apiladora automática para la fabricación de células en bolsaCategorías

© Derechos de autor: 2026 Xiamen Tmax Battery Equipments Limited Reservados todos los derechos.

IPv6 red compatible