Unirse TMAX, convertirse en un agente!

Unirse TMAX, convertirse en un agente!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Número de artículo.:

TMAX-A-007Pago:

L/C, T/T, Western Union, Credit Cards, PaypalOrigen del producto:

ChinaPuerto de embarque:

Xiamen PortPlazo de entrega:

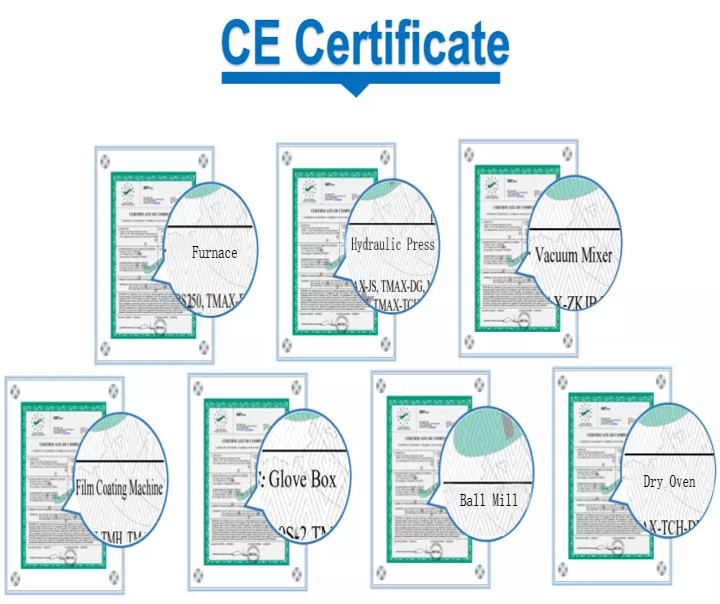

5 Dayscertificado :

CE, IOS, ROHS, SGS, UL Certificategarantía :

Two years limited warranty with lifetime technical support

Funciones

â Este equipo es adecuado para baterías de iones de litio de ánodo y cátodo Z con ensamblaje laminado de membrana de aislamiento, membrana de aislamiento externa automática en el grupo polar, corte automático del diafragma, adhesivo de bloqueo de terminación automática. cinta, borrado automático, recogida manual de baterías.

Características

â El ánodo y el cátodo son administradores de configuración única, la hoja del canalâcon estructura de elevación en tiempo real;

â Una ligera curvatura, un cepillo, una sacudida y una ventosa flexible pueden prevenir eficazmente el fenómeno de absorción de múltiples placas;

â Posicionamiento preciso secundario, asegúrese del grado de alineación de la placa;

â Dispositivo de eliminación de polvo del equipo, puede enfocar el colector de polvo astillado y garantizar la limpieza mecánica de la mesa;

â Película catódica con garra de presión de ánodo y cátodo, previene el fenómeno de contaminación cruzada;

â Seque el viento con iones de membrana de aislamiento, retire la membrana de aislamiento electrostática;

â Instalación de posicionamiento secundario de sensor ultrasónico para detectar repetición o falta de pastillas;

â Adopta una máquina laminadora con servoaccionamiento, puede hacer que la tensión entre las capas de la hoja sea uniforme;

â Lechón amortiguador sin rastro importado, eficaz para prevenir la aparición de impresión de placa de succión y fenómeno de indentación;

â Con funciones de reciclaje de diafragma y la primera pieza de función de corrección de diafragma.

Ofreceremos máquina apiladorae de alta precisión con muchas funciones avanzadas para garantizar una estabilidad,

apilamiento de electrodos repetible y preciso.

Parámetros técnicos (para referencia)ï¼

|

ARTÍCULO |

HBZDP150 |

HBZDP250 |

HBZDP300 |

|

Medida |

1800*1600*1950 mm (largo*ancho*alto) |

1920*1850*1950 mm (largo*ancho*alto) |

2100*1850*1950 mm (largo*ancho*alto) |

|

peso |

Aproximadamente 1,0 T |

Aproximadamente 1,2 T |

Aproximadamente 1,3 T |

|

poder |

CA 220 V/50 HZ, 3,0 kw |

CA 220 V/50 HZ, 3,0 kw |

CA 220 V/50 HZ, 3,0 kw |

|

Fuente de aire |

ï¼0.6Mpa, 30L/min |

ï¼0.6Mpa, 30L/min |

ï¼0.6Mpa, 30L/min |

|

Fuente de vacío |

â¤-0.09Mpa, 15L/s |

â¤-0.09Mpa, 15L/s |

â¤-0,09 MPa, 15 l/s |

|

Rango aplicable |

Largo: 50-150 mm, Ancho: 35-90 mm, Fondo: 5-30 mm |

Largo: 100-250 mm, Ancho: 60-150 mm, Fondo: 5-50 mm |

Largo: 150-300 mm, Ancho: 100-200 mm, Fondo: 5-50 mm |

|

Capacidad |

1,1-1,4 s/placa |

1,2-1,6 s/placa |

1,3-1,7 s/placa |

|

Acción |

ï¼99% |

ï¼99% |

ï¼99% |

1 paquete estándar exportado: protección anticolisión interna, embalaje externo en caja de madera para exportación.

2 Envío por expreso, aéreo o marítimo según los requisitos del cliente para encontrar la forma más adecuada.

3 responsable del daño durante el proceso de envío, cambiará la pieza dañada de forma gratuita.

Anterior :

Máquina apiladora automática de alta precisión para la fabricación de células en bolsaPróximo :

Máquina de recubrimiento automática rollo a rollo para la producción de electrodos de bateríaCategorías

© Derechos de autor: 2026 Xiamen Tmax Battery Equipments Limited Reservados todos los derechos.

IPv6 red compatible