Unirse TMAX, convertirse en un agente!

Unirse TMAX, convertirse en un agente!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Número de artículo.:

TMAX-EFQB-200Pago:

L/C, T/T, Western Union, Credit Cards, PaypalOrigen del producto:

ChinaPuerto de embarque:

Xiamen PortPlazo de entrega:

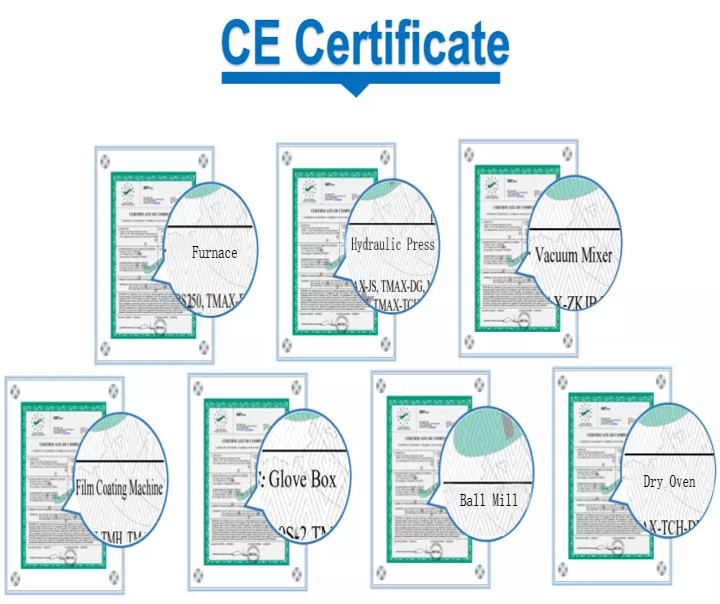

5 Dayscertificado :

CE, IOS, ROHS, SGS, UL Certificategarantía :

Two years limited warranty with lifetime technical support

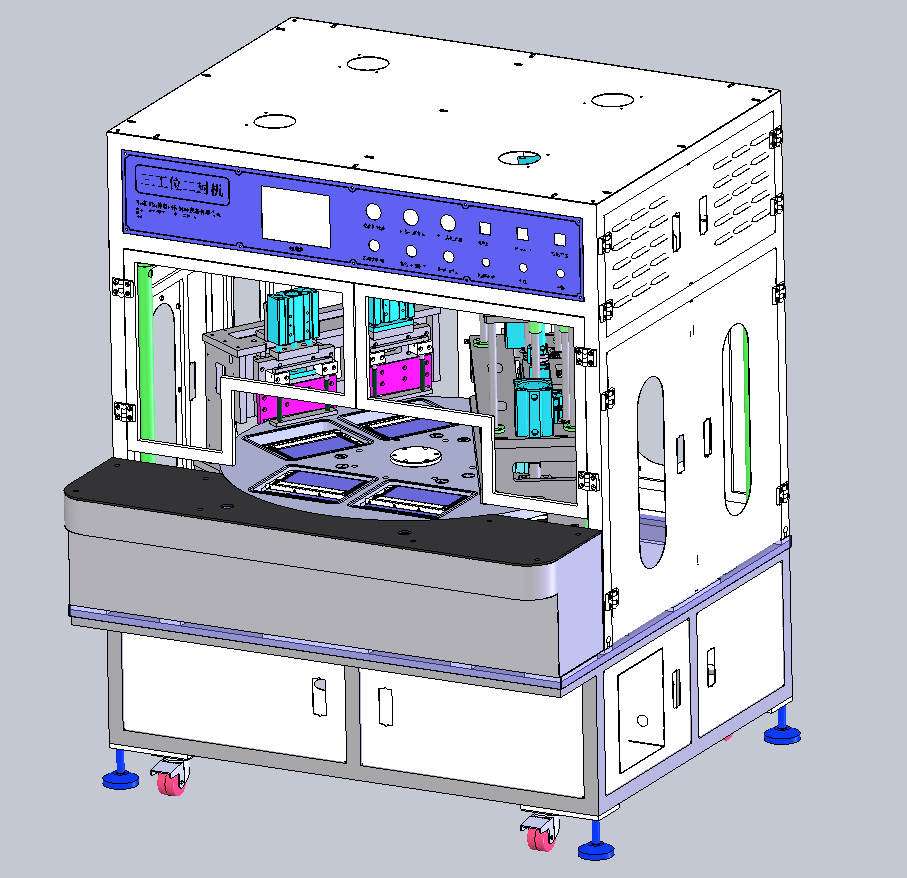

Introducción

Esta máquina es adecuada para el sellado final al vacío de celdas de bolsas de litio y la eliminación de los bordes de las bolsas de aire. Coloque manualmente la celda de la batería en el mecanismo de alimentación del plato giratorio. La dirección de avance de la batería es hacia abajo. Gire la alimentación a través del plato giratorio. (La plataforma giratoria coloca 3 posiciones y gira 120 grados cada vez). La plataforma giratoria de alimentación gira a su posición y comienza a sellar los bordes. Ingrese a la estación de recorte a 120 grados para recortar los bordes. Después de recortar, gire 120 grados para volver a la posición de carga, retire manualmente el material y repita la operación anterior.

Estructura del equipo

1. Adoptando una estructura de alimentación de plato giratorio, precisión del divisor del plato giratorio: ± 0,1 mm

2. Precisión de alineación del paquete de la máquina: ± 0,1 mm, paralelismo del cabezal: ± 0,01 mm

3. Rango de ajuste del tiempo de sellado: 1 s-30 s, precisión de ajuste: ± 0,1 mm

4. El tiempo de termosellado y el tiempo de vacío se configuran en la pantalla táctil: la presión de envasado se ajusta en el panel de operación,

5. La precisión de la temperatura se controla dentro del rango de ± 2 °C y se controla mediante el programa PLC. Si la temperatura es demasiado alta o demasiado baja, la alarma se detendrá automáticamente

6. El paquete adopta una estructura de doble cabezal y doble cavidad;

7. El tubo calefactor utiliza 700 vatios; el rango de temperatura de trabajo del cabezal es RT~300 °C;

8. El diámetro del cilindro de culata superior es de 63 mm y el diámetro del cilindro de bayoneta es de 25 mm;

9. Las puertas y ventanas están hechas de pintura para hornear de chapa y el extractor de aire está instalado en la parte superior;

10. La bolsa de aire de corte adopta una estructura de corte de doble filo, cada par de cortadores de borde corta los bordes de forma independiente;

11. El filo está hecho de acero para herramientas resistente al desgaste y a la corrosión, y la vida útil del cortador es 600.000 veces;

Especificaciones

|

Fuente de alimentación |

CA 220 V/50 Hz; Potencia: 4,5 KW |

|

Aire comprimido |

0,4 ~ 0,6 Mpa 20 l/min |

|

Longitud aplicable |

â¤200 mm |

|

Ancho aplicable |

â¤120 mm |

|

Ancho del airbag |

â¤70 mm |

|

Cortador doble de doble cavidad |

Sí |

|

Función de perforación |

Sí |

|

Función de prensado y moldeado plano |

Sí |

|

Longitud efectiva del cortador |

200 mm |

|

Ancho de corte |

4,5 mm |

|

Número de baterías que se pueden colocar |

â¤10 (doble cavidad) |

|

Capacidad de producción |

â¤60 ~ 80PPM |

|

Peso del equipo |

alrededor de 500 kg |

|

Fuente de vacío |

â¤â95Kpa |

|

Dimensiones |

1390 * 1240 * 1700 mm (largo x ancho x alto) |

1 paquete estándar exportado: protección anticolisión interna, embalaje externo en caja de madera para exportación.

2 Envío por expreso, aéreo o marítimo según los requisitos del cliente para encontrar la forma más adecuada.

3 responsable del daño durante el proceso de envío, cambiará la pieza dañada de forma gratuita.

Anterior :

Cortador automático del electrodo de batería de la máquina que corta con tintas del electrodo de batería de la célula de la bolsaPróximo :

Troqueladora automática de células de bolsa de máquina cortadora de electrodos de bateríaCategorías

© Derechos de autor: 2026 Xiamen Tmax Battery Equipments Limited Reservados todos los derechos.

IPv6 red compatible