Unirse TMAX, convertirse en un agente!

Unirse TMAX, convertirse en un agente!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Número de artículo.:

TMAX-DP-150Pago:

L/C, T/T, Western Union, Credit Cards, PaypalOrigen del producto:

ChinaPuerto de embarque:

Xiamen PortPlazo de entrega:

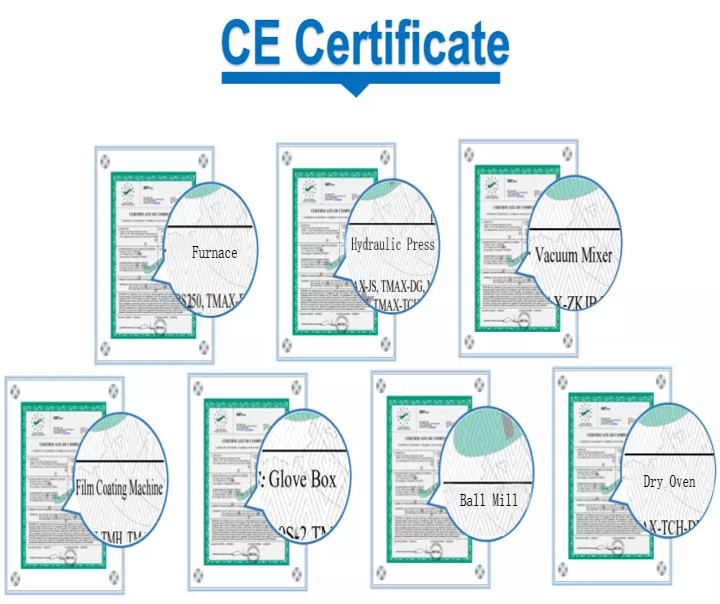

5 Dayscertificado :

CE, IOS, ROHS, SGS, UL Certificategarantía :

Two years limited warranty with lifetime technical support

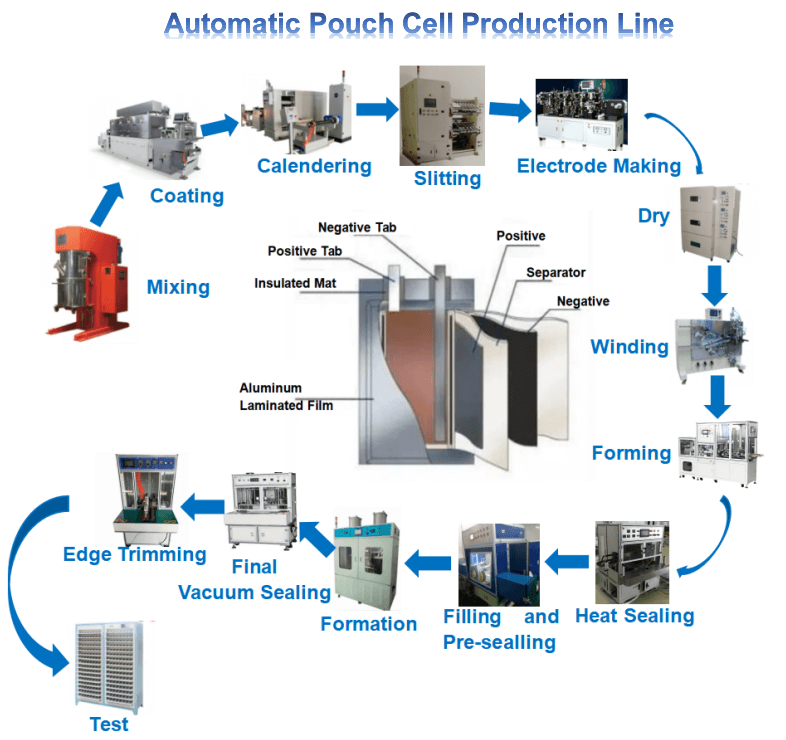

Introducción

TMAX-DP-150 es una máquina apiladora semiautomática de alta precisión con muchas funciones avanzadas para garantizar un apilamiento de electrodos estable, repetible y preciso. Adopta el glifo "Z" laminado.

Funciones avanzadas

1 control de pantalla táctil PLC con fácil configuración de condiciones.

2 Apilamiento continuo en forma de "Z" con un separador.

3 Recogida y apilamiento automático de electrodos mediante manipulador de succión al vacío.

4 A través de cuatro manipuladores para retirar el electrodo de la caja de material se coloca la segunda plataforma, después de la calibración, luego se coloca en la plataforma de laminación, laminada con un dispositivo de sujeción automático en el escenario.

5 Rotores desenrolladores para alimentación de película separadora.

6 Control de tensión automática para la entrega de la película separadora.

Especificación

Modelo

Máquina apiladora semiautomática TMAX-DP-150

Tamaño de batería adecuado

Espesor H (mm)

5-20

Ancho ancho (mm)

30-90

Longitud L (mm)

80-150

Longitud de la pestaña Q (mm)

Qâ¤20

Ancho de pestaña (mm)

â¤20

Parámetro tecnológico

Velocidad de apilamiento

1,3-1,5 s/unidad

Precisión del registro

±0,5 mm

Cantidad de apilamiento

Se puede configurar

Porcentaje de aprobación

â¥98%

Poder

4kW

Peso

800kg

Dimensión (largo*ancho*alto)

1250*1200*1850 mm

Tamaño de los materiales

Electrodo

Longitud: 80-150 mm

Ancho: 30-90 mm

Espesor: 0,07-0,25 mm

Pestaña

Longitud: â¤20mm

Ancho: 8-20 mm

Separador

Longitud: en rollo

Ancho: 90-150 mm

Espesor: 0,02-0,04 mm

Diámetro interior: Ï76,2 mm

Diámetro máximo de salida: Ï300

1 paquete estándar exportado: protección anticolisión interna, embalaje externo en caja de madera para exportación.

2 Envío por expreso, aéreo o marítimo según los requisitos del cliente para encontrar la forma más adecuada.

3 responsable del daño durante el proceso de envío, cambiará la pieza dañada de forma gratuita.

Anterior :

Máquina automática de prensado en caliente para la producción de células en bolsaPróximo :

Máquina de recubrimiento automática de electrodos de batería para la fabricación de baterías de litioCategorías

© Derechos de autor: 2026 Xiamen Tmax Battery Equipments Limited Reservados todos los derechos.

IPv6 red compatible