Unirse TMAX, convertirse en un agente!

Unirse TMAX, convertirse en un agente!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Número de artículo.:

TMAX-A-023Pago:

L/C, T/T, Western Union, Credit Cards, PaypalOrigen del producto:

ChinaPuerto de embarque:

Xiamen PortPlazo de entrega:

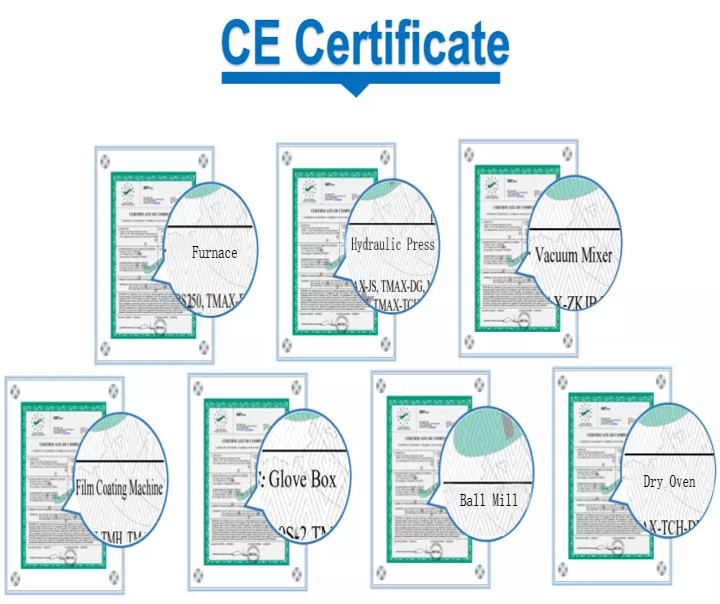

5 Dayscertificado :

CE, IOS, ROHS, SGS, UL Certificategarantía :

Two years limited warranty with lifetime technical support

Funciones

â Adecuado para equipos de producción de automóviles de extracción, sellado, bolsas de aire precortadas, recorte, bridas y conformado en caliente. (Agregar prueba, código de escaneo, pesaje y funciones de carga y descarga automática de material son opcionales).

Características

â Mano mecánica para cargar el material en el cuerpo de sellado, después de completar la carga, la cavidad se cierra automáticamente, perforación, infusión, encapsulaciónï¼

â Función de bolsa de aire precortada, eliminación del exceso de bolsa de aire, evita la bolsa de aire en la contaminación del electrolito residualï¼

â Después de la función de prueba de cortocircuito de la batería de encapsulación, el proceso, después de la prueba, el material NG no pasa al siguiente nivel automáticamente;

â Bolsa de aire respectivamente en dos lados y en el lado de sellado lateral, posicionamiento de la escisión y rizado, asegura la precisión del corte;

â Después de doblar la forma del borde de la batería de hierro, bloquee el borde del hierro, asegúrese de que la batería esté en buen estado;

â Función de pesaje después del moldeo, entrada de datos de pesaje a la computadora;

â Precisión de recorte de ± 0,15 mm;

â Antes del embalaje para la reorientación secundaria de la batería, precisión de la ubicación del encapsulado ± 0,15 mm;

â 1 juego de cada celda tiene un servomecanismo independiente, presión a través del control del sensor de presión y pantalla de salida;

â Use un cuchillo para perforar, las bolsas de aire en el borde exterior del espacio cortado, las baterías en el interior bloquean la velocidad de descarga de gas, ponen fin a la inyección de electrolito, controlan el volumen de fluido de bombeo y reducen la contaminación del electrolito. a la cabeza y la cavidad.

Parámetros técnicos (para referencia)ï¼

|

ARTÍCULO |

HBS-CYCX100 |

HBS-CYCX150 |

HBS-CYCX300 |

|

Medidas |

(Largo*An*Al): 2800*1400*2300 mm |

(Largo*An*Al): 4800*2300*2400 mm |

(Largo*An*Al): 4500*2700*2300 mm |

|

Peso |

Acerca de 2,0T |

Aproximadamente 2,5T |

Aproximadamente 3,0T |

|

Poder |

CA 220 V/50 Hz, 15 kW |

CA 220 V/50 Hz, 15 kW |

CA 220 V/50 HZ, 15 kW |

|

Fuente de aire |

â§0.6Mpa, 50L/Min |

â§0,6 Mpa, 50 l/min |

â§0.6Mpa, 50L/Min |

|

Fuente de vacío |

â¤-95Kpa, 400L/Min |

â¤-95Kpa, 400L/Min |

â¤-95Kpa, 400L/Min |

|

Rango aplicable |

Largo: 40-100 mm, Ancho: 40-80 mm, Fondo: 3-10 mm |

Largo: 50-160 mm, Ancho: 50-120 mm, Fondo: 3-15 mm |

Largo: 100-300 mm, Ancho: 100-300 mm, Fondo: 4-15 mm |

|

Capacidad |

â§10PPM(2 piezas/cavidad, â¤20s) |

â§10PPM(2 piezas/cavidad, â¤20s) |

â§4PPM(1 pieza/cavidad, â¤25s) |

|

Acción |

â§99,5% |

â§99,5% |

â§99,5% |

1 paquete estándar exportado: protección anticolisión interna, embalaje externo en caja de madera para exportación.

2 Envío por expreso, aéreo o marítimo según los requisitos del cliente para encontrar la forma más adecuada.

3 responsable del daño durante el proceso de envío, cambiará la pieza dañada de forma gratuita.

Anterior :

Máquina de llenado de electrolitos completamente automática para producción de células de bolsa/batería EVPróximo :

Máquina automática de horno de cocción para fabricación de células de bolsa de litioCategorías

© Derechos de autor: 2026 Xiamen Tmax Battery Equipments Limited Reservados todos los derechos.

IPv6 red compatible