Unirse TMAX, convertirse en un agente!

Unirse TMAX, convertirse en un agente!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Número de artículo.:

TMAX-BD-30000SL-PLTPago:

L/C, T/T, Western Union, Credit Cards, PaypalOrigen del producto:

ChinaPuerto de embarque:

Xiamen PortPlazo de entrega:

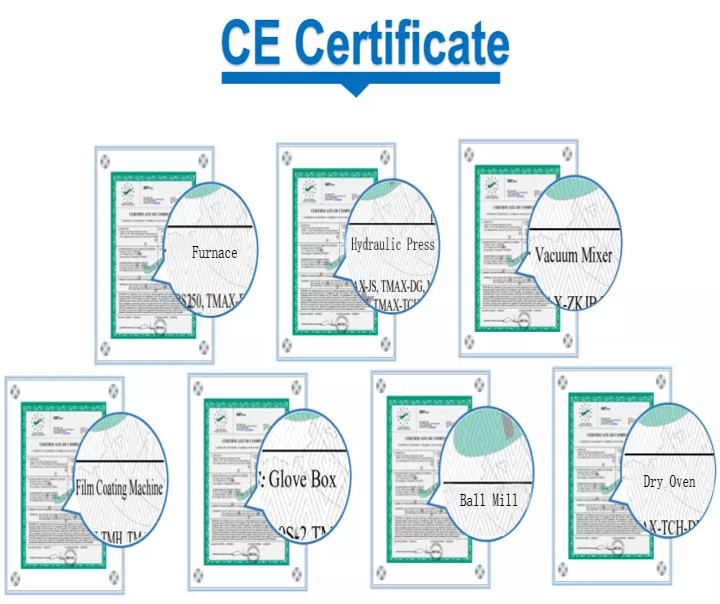

5 Dayscertificado :

CE, IOS, ROHS, SGS, UL Certificategarantía :

Two years limited warranty with lifetime technical support

IãIntroducción al principio del sistema

El disolvente NMP se evapora después de calentarlo en el proceso de recubrimiento. El equipo de recuperación de NMP condensa el gas volátil paso a paso, reduce gradualmente la concentración de NMP en el gas mediante condensación de varias etapas y finalmente descarga el gas purificado.

IIãComposición del sistema

El sistema de recuperación consta de un servidor de recuperación de NMP solvente, un sistema de control inteligente, un sistema de conductos de aire, un sistema de vías fluviales, un sistema de recolección de NMP solvente y un sistema de tratamiento de gases de cola.

Introducción al equipo

1 .Propósito del equipo

Los equipos de la serie QR se utilizan principalmente en la industria de baterías de litio; Es un equipo de protección ambiental de alto rendimiento para el tratamiento de gases residuales de NMP generados en el proceso de recubrimiento de la fabricación de baterías de litio.

2 .Características del equipo

El gas residual de NMP se trata y purifica mediante enfriamiento y pulverización con agua, lo que tiene una función de recuperación y un efecto de purificación de alta eficiencia.

El equipo es fácil de operar con instrucciones claras.

Diseño combinado, los componentes principales se pueden desmontar y mantener fácilmente.

Recuperación de NMP de alta eficiencia, con altos beneficios económicos para los usuarios

3ãPrincipales parámetros técnicos del equipo:

2.3.1.NMP Parámetros técnicos del equipo de recuperaciónï¼

A. Temperatura de escape: ⤠120 â

B. Volumen de aire de tratamiento: 30000m ³/ H (regulación de velocidad de frecuencia variable)

C. Tasa de recuperación: ⥠95%, error estacional ⤠3%

D. Concentración de líquido residual recuperado ⥠85%, error estacional ⤠3%

E. Concentración de emisiones de escape: <50 mg/m ³ Es decir. <12,3 ppm

F. Potencia operativa del sistema de recuperación: 25kW *1 juego

4. Otros requisitos de equipo

Cada máquina de recubrimiento positivo está equipada con 1 juego de equipo de recuperación de NMP

â Requisitos de alimentación del sistema: CA 380 V, 50 Hz, cinco cables trifásicos.

â¡ Tamaño del dispositivo de recuperación de la máquina principal: L3000*W1800*H2500

⢠Área de piso: 10000*2000

⣠Tamaño de la torre de purificación: Φ 1500*3200.

⤠Frío: 36P.

⥠Peso neto de cada conjunto de equipos: 2T, peso operativo: 4T.

… Conducto de aire; Fabricado en chapa de hierro galvanizado y acero inoxidable. (de lo contrario negociado con el cliente)

⧠Tubería de agua en circulación: tubería de PVC.

⨠El interruptor de aire Chint, el contacto de CA, el relé térmico, el relé de protección de secuencia de fases y el relé de tiempo se utilizan como accesorios eléctricos.

â© Diseñe un sistema de control automático con alarma intermitente.

⪠Para una mejor disipación del calor, el sistema utiliza una torre de enfriamiento independiente para suministrar agua de enfriamiento en circulación.

1 paquete estándar exportado: protección anticolisión interna, embalaje externo en caja de madera para exportación.

2 Envío por expreso, aéreo o marítimo según los requisitos del cliente para encontrar la forma más adecuada.

3 responsable del daño durante el proceso de envío, cambiará la pieza dañada de forma gratuita.

Anterior :

Máquina automática de fabricación y bobinado de electrodos para producción de celdas cilíndricas 18650 21700 26650 32700Próximo :

Máquina bobinadora completamente automática para la fabricación de celdas cilíndricas de litioCategorías

© Derechos de autor: 2026 Xiamen Tmax Battery Equipments Limited Reservados todos los derechos.

IPv6 red compatible