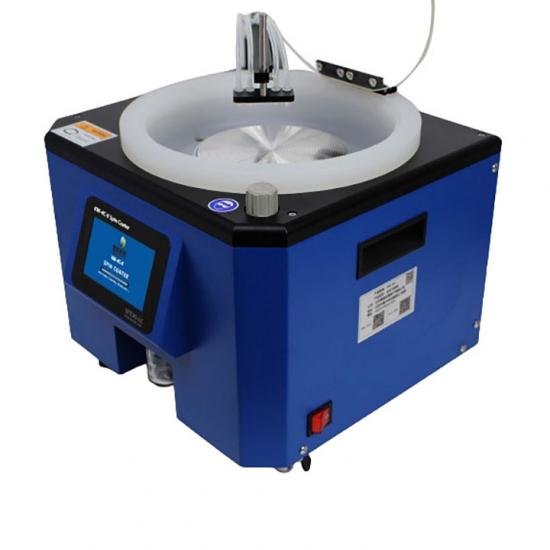

Spin Coating Machine: A Comprehensive Guide

A spin coating machine is an essential piece of equipment in various industries, especially in the fields of electronics, optics, and materials science. This machine is used to apply uniform thin films onto substrates by spinning the substrate at high speeds. This guide covers the working principle, key components, process steps, applications, advantages, and challenges of spin coating machines.

Working Principle

The spin coating process involves depositing a small amount of liquid solution (typically a polymer, photoresist, or other material) onto the center of a substrate. The substrate is then rapidly spun, causing the solution to spread out and form a thin, uniform film due to centrifugal force. The thickness of the resulting film is controlled by the spin speed, spin time, and viscosity of the solution.

Key Components

1.Chuck: The platform that holds and rotates the substrate. It is usually vacuum-sealed to secure the substrate during spinning.

2.Motor: Drives the chuck and controls the spin speed and acceleration.

3.Dispensing System: Deposits the coating solution onto the substrate. This can be done manually or via an automated dispensing system.

4.Controller: Manages the spin speed, time, and acceleration/deceleration profiles.

5.Cover: Encloses the spinning process to prevent contamination and ensure safety.

Process Steps

Substrate Preparation: The substrate (e.g., silicon wafer, glass slide) is cleaned to remove any contaminants that might affect the film uniformity.

Solution Deposition: A small amount of the coating solution is dispensed onto the center of the substrate.

Spinning: The substrate is rapidly spun, causing the solution to spread out and form a thin film. The spin speed and time are carefully controlled to achieve the desired film thickness.

Drying/Curing: The coated substrate is dried or cured, often by heating, to solidify the film and remove any remaining solvent.

Applications

Microelectronics: Applying photoresists and other materials in the fabrication of semiconductor devices.

Optics: Coating lenses and optical components with anti-reflective or protective layers.

Materials Science: Creating thin films for research and development in nanotechnology and surface science.

Solar Cells: Depositing thin film materials in the production of photovoltaic cells.

Medical Devices: Coating implants and other medical devices with biocompatible materials.

Advantages

Uniformity: Spin coating can produce highly uniform thin films with precise control over thickness.

Versatility: Capable of coating a wide range of materials and substrates.

Speed: The process is quick, making it suitable for both research and industrial production.

Scalability: Spin coating can be easily scaled from laboratory settings to large-scale manufacturing.

Challenges

Material Waste: Excess solution is often flung off the substrate during spinning, leading to material waste.

Limited Substrate Size: The size of the substrate that can be coated is limited by the size of the spin coater.

Solvent Handling: Proper handling and disposal of solvents are required to ensure safety and environmental compliance.

Edge Bead Formation: A thicker ring, or "edge bead," can form around the perimeter of the substrate, which may need to be removed in subsequent processing steps.

Development Challenges

Uniformity Control: Achieving uniform film thickness over large areas and diverse substrate shapes remains a technical challenge.

Material Compatibility: Developing spin coating processes compatible with new and emerging materials.

Process Optimization: Optimizing parameters to minimize material waste and improve coating efficiency.

Automation: Integrating more advanced automation and control systems to improve reproducibility and throughput.

Conclusion

The spin coating machine is a versatile and powerful tool for applying uniform thin films to a variety of substrates. Its applications span across numerous industries, from microelectronics to medical devices, making it indispensable in both research and production environments. While challenges such as material waste and edge bead formation exist, ongoing advancements in technology and process optimization continue to enhance the capabilities and efficiency of spin coating machines.