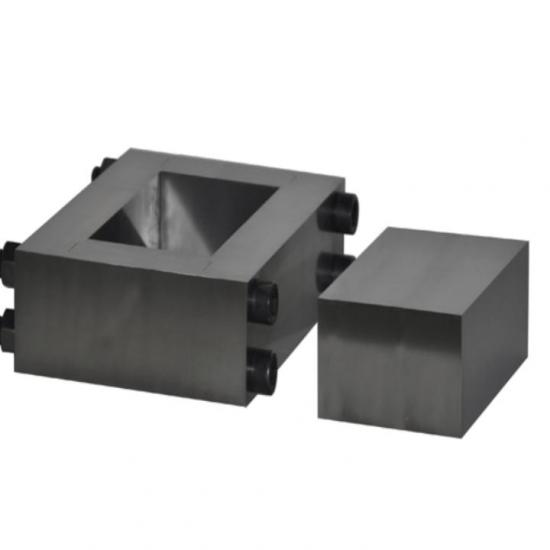

Hydraulic Press Square Mold: A Key Tool in Manufacturing

A hydraulic press square mold is a critical component used in manufacturing processes where high pressure is required to shape materials into square or rectangular forms. This equipment is essential in industries such as automotive, aerospace, construction, and composites, where precision and strength are paramount.

● Key Features of Square Press Die

1. Robust Design: Typically made from high-strength materials, these molds can withstand the immense pressure exerted during the pressing process.

2. Customizable Dimensions: Square molds can be tailored to various sizes and shapes, allowing for flexibility in production to meet specific requirements.

3. High Pressure Capability: Hydraulic presses can generate significant force, enabling the molding of dense materials, including metals, plastics, and composites.

4. Precision Engineering: Molds are engineered to provide precise dimensions and surface finishes, ensuring high-quality end products.

● Common Applications

1. Metal Forming: Used in forging and stamping operations to create components like brackets, frames, and structural parts.

2. Composite Manufacturing: Essential for shaping composite materials into desired forms, often used in aerospace and automotive applications for lightweight components.

3. Plastic Molding: Employed in the production of plastic parts, such as housings and containers, where uniformity and strength are required.

4. Ceramic Production: Used to form ceramic components through pressure-assisted densification, improving mechanical properties and reducing porosity.

● Advantages of Using Hydraulic Press Square Molds

1. Efficiency: The ability to produce multiple parts in a single press cycle enhances productivity and reduces manufacturing time.

2. Quality Control: Hydraulic pressing provides consistent pressure distribution, resulting in uniformity and high-quality finishes across produced parts.

3. Versatility: These molds can be used with a wide range of materials, making them suitable for diverse applications.

4. Cost-Effectiveness: While the initial investment may be high, the long-term benefits of efficiency and reduced waste can lead to significant cost savings.

● Considerations for Hydraulic Press Square Molds

1. Maintenance: Regular inspection and maintenance are necessary to ensure the longevity and performance of molds and presses.

2. Material Selection: Choosing the right materials for both the mold and the components being produced is crucial for achieving desired properties and performance.

3. Safety: Operators must be trained in safety protocols to handle hydraulic presses, as they involve high pressures that can pose risks if not managed properly.

● Conclusion

A hydraulic press square mold is an essential tool in modern manufacturing, providing the precision and strength required to shape materials into high-quality components. Its versatility across different industries makes it a valuable asset in achieving efficient production processes. As manufacturing technologies continue to advance, hydraulic press molds will remain integral in driving innovation and enhancing productivity in various applications.