Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with Laboratory equipments, technology, etc. We have total manufacturing facilities of around 2, 000 square meters and more than 100 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

An automatic hydraulic hot press is a sophisticated piece of equipment designed to apply both heat and hydraulic pressure in an automated fashion, making it highly efficient for processes that require precise control over temperature and pressure. This type of press is commonly used in industries such as composites manufacturing, rubber processing, plastics molding, wood laminate production, and various research and development applications where repeatability and consistency are crucial.

Key Features of an Automatic Hydraulic Hot Press

1. Advanced Heating System

Heated Platens: Equipped with heated platens made from materials with excellent thermal conductivity, ensuring uniform heating across the entire surface.

Temperature Range and Precision: Capable of achieving temperatures ranging from around 30°C up to 450°C or higher, with precise control within tight tolerances to ensure consistent quality across batches.

Thermal Insulation: High-quality insulation minimizes heat loss, contributing to energy efficiency and protecting internal components.

2. Hydraulic Pressure Application

High Force Capacity: These presses can generate substantial force, often ranging from several tons to hundreds of tons, suitable for compacting materials under high pressure.

Automated Pressure Control: Offers fine, automated control over the applied pressure through programmable settings, allowing operators to set exact pressures for different stages of the pressing cycle.

3. Programmable Control Systems

PLC (Programmable Logic Controller) or HMI (Human-Machine Interface): Modern presses come equipped with advanced interfaces that allow operators to program specific parameters like temperature, pressure, dwell time, and cooling rates.

Recipe Management: Stores multiple recipes for different materials and processes, enabling quick changeovers between jobs without manual reconfiguration.

4. Automation and Integration

Automatic Operation: The entire process—from loading and positioning the material to applying pressure and heat, holding at desired conditions, and unloading the finished part—can be automated according to pre-set programs.

Integration with Other Systems: Can be integrated into larger manufacturing lines or connected with robotic systems for fully automated operations, enhancing productivity and reducing labor costs.

5. Safety Features

Emergency Stop Buttons: Provides immediate shutdown capabilities to enhance operator safety.

Pressure Relief Valves: Protect against overloading by releasing excess pressure, ensuring both operator safety and equipment longevity.

Interlocks and Guarding: Prevents access to hazardous areas during operation, ensuring safe handling.

6. Data Acquisition and Analysis

Real-Time Monitoring: Sensors provide real-time data on critical parameters like temperature, pressure, and cycle time, allowing for adjustments if necessary.

Quality Assurance: Data logging capabilities enable detailed tracking of each operation, supporting quality control efforts and compliance with industry standards.

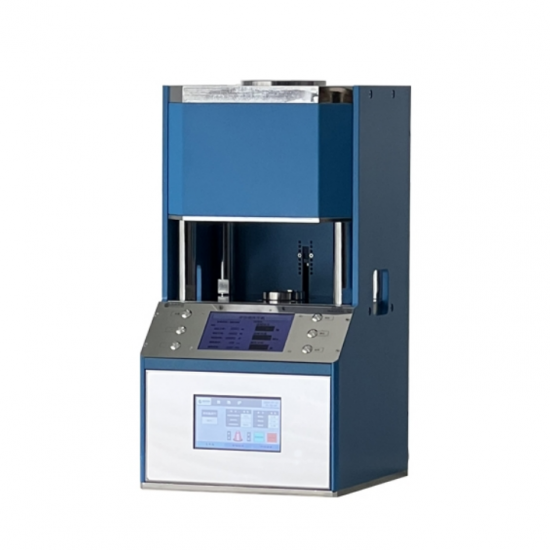

Automatic High Temperature Hot Press

Applications

Composite Manufacturing: Used for curing composite materials, including carbon fiber reinforced polymers (CFRP), glass fiber reinforced polymers (GFRP), and other advanced composites.

Rubber Processing: Ideal for vulcanizing rubber products, ensuring they achieve the desired mechanical properties.

Plastics Molding: Suitable for compression molding of thermoplastics and thermosetting plastics, including intricate parts and components.

Wood Lamination: Utilized in producing laminated wood products, such as plywood and veneer panels, where heat and pressure are required to bond layers together.

Research and Development: Provides a controlled environment for developing new materials and testing their properties under specific conditions of temperature and pressure.

Choosing the Right Automatic Hydraulic Hot Press

When selecting an automatic hydraulic hot press, consider factors such as the required temperature and pressure ranges, the types of materials you will be working with, the precision needed for your experiments or production processes, available space in your facility, and any specific features relevant to your intended use (e.g., heated platens, programmable controls). Investing in an automatic hydraulic hot press tailored to your needs can greatly enhance operational efficiency, product quality, and overall competitiveness in your market. Whether you're focusing on industrial production or laboratory research, the right automatic hydraulic hot press can significantly improve your outcomes by providing consistent, repeatable results.